Part One

Model (MOC) by Tim Scheiter from Rebrickable.com

Bosley & Co’s Point of View …

So, with the river levels rising … the cabins need to be raised, the cattle paddock raised or the cattle relocated, and stores to be got in by boat or helicopter. Bosley decided they would acquire a tower crane and that it would be a permanent fixture in the village.

Jackie’s crane mounted on Jed’s truck, transferred onto a remaindered railway dolly, turned into be a good helper-crane. Great at helping to transport tower crane parts from the barges, and great at raising them to where the construction was happening.

The Build From My Point of View …

Getting the parts probably was not the hardest part but certainly seems so with postage becoming the real spoke in the wheel, after five parcels from five different far-flung places. This is the thing about living in Australia. Vast internal distances and even larger external distances which all equal to pricey postage.

And I still don’t have all the parts I need and though it’s only a short list at the moment, its length will increase as I start to modify the original design.

Modifying Before I’ve even build it? …

Yes, unfortunately. As always, space is constrained. Second, a few videos of real-life lone tower cranes swaying and breaking up in high winds, convinced me that even the stability of a Technic crane might need bolstering by being connected to its builds.

Beginning to make that happen, I found that I was using parts that will probably be needed elsewhere. The first really big problem I hit was a lack of two vital elements. Struts and panels. Just unable to get enough of either of them. I have only 5 of the panels, and 8 of the struts.

While I would’ve really enjoyed to build the whole thing without any hiccups, that was not to be. At this stage I thought I might be able to fix the tower on a base-plate with ordinary Lego pieces, support it that way.

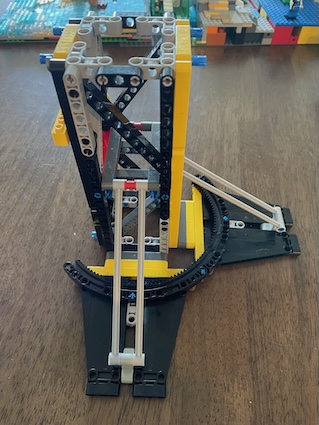

That idea turned into fixing the four-sided base of the tower to a Lego base-plate with the help of Technic bricks. Which worked very well on two opposite sides. These bricks lift the structure about 1 millimeter above the studs but because multiple pins on each side connect the two, there’s a strong and stable joint. Leaving me with the right number of strut-pieces for the jib/boom.

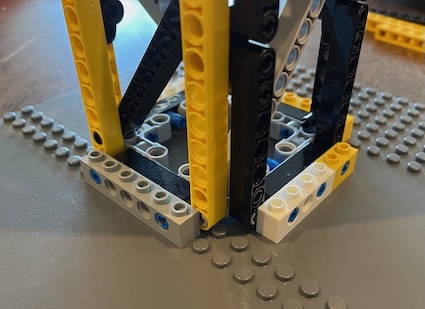

So what happened? While there are eleven studs between the first pair of two opposite sides—and there need to be—there are eleven-and-a-half studs between the second pair of opposite sides. I rebuilt the whole thing several times, tightened everything that could be tightened, but got the same result every time. By then quite frustrated.

After a while remembered the ancient roads base-plate in my collection. This is the result. I’ve done away with the need for the second pair of opposite sides to be fastened to the base-plate. They are wedged pretty tight. In the photo below you can just about see the problem, the white brick does not line up with the studs.

That left a final concern. Without the struts-and-panels stabilization system the tower structure was so rickety that I was afraid that with more weight on it from another section of tower, a boom and trolley, the machinery in the middle, and the power and battery system on the other end, the tower would just twist and collapse. I inserted two panels made of 7 x 7-beams midway the stage.

These are probably overkill, since I will be fastening this stage to two fire escape blocks, part of the new village build. I put them in for peace of mind.